What Is a Heavy plate feeder: Structure Principle and Core Functions

The plate feeder is a quantitative feeding device specifically designed for continuous conveying systems of bulk materials. Its core function is to realize continuous and uniform feeding and transfer of materials from upstream storage units—such as hoppers and transfer chutes—to downstream equipment, including crushers, batching systems, or transport devices like belt conveyors.

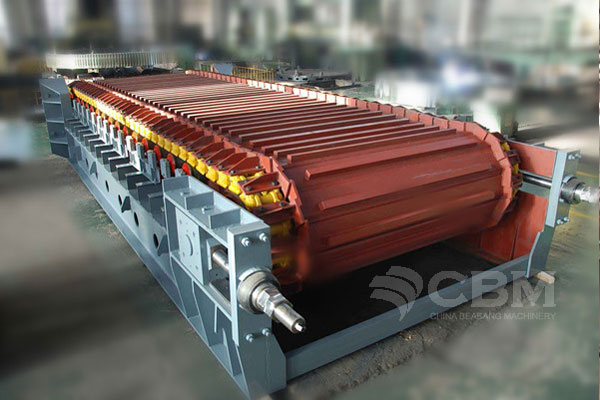

Structural Principle

The equipment operates through a drive unit (typically a motor and reducer assembly or hydraulic motor) that drives a closed-loop traction chain (usually an apron-type chain). This, in turn, moves the conveying pans (carrying plates) attached to the chain in synchronization, smoothly transporting materials from the feed end to the discharge end.

- Conveying pans:Made of high-strength wear-resistant steel plates (e.g., Q345B or higher-grade alloy steel), formed by rolling or welding. The surfaces are hardened through overlay welding or hard alloy coating, enabling them to withstand strong impact forces from falling materials and long-term abrasion. This ensures structural reliability under heavy-duty working conditions.

- Hopper coordination:To prevent direct free-fall impact on the feeder surface—which could cause plate deformation or chain overloading—the outlet gate or guide chute of the hopper must retain a buffer layer of material. This creates a “soft landing” effect, protecting the feeder surface and drive system.

Typical Applications

The Heavy plate feeder serves as core equipment in large-scale mineral processing plants, cement clinker production lines, and raw material handling systems. It is mainly used for:

Connecting hoppers to primary crushers:It delivers large-size, high-density materials (e.g., raw ore ≤1200 mm, limestone blocks) at a stable rate to jaw crushers or gyratory crushers, preventing overload or material blockage caused by uneven feeding.

Short-distance transport of large bulk materials:It enables directional conveying of massive and heavy materials—sometimes weighing several tons—with densities up to 4.5 t/m³ (e.g., iron ore) over short distances (≤50 m), handling loads that conventional belt conveyors cannot manage.

Technical Features of Heavy Plate Feeders

To adapt to heavy load, high impact, and dusty conditions, the Heavy plate feeder integrates multiple targeted design optimizations:

1. High Load-Bearing and Impact-Resistant Design

The machine adopts a modular high-strength frame structure. The main beams and support members are optimized through finite element analysis (FEA) to ensure no plastic deformation or loosening of joints under massive impact loads (single-point forces up to tens of tons) and heavy-load startup torque (≥1.5× rated torque). This guarantees continuous, full-capacity operation.

2. Durable Materials and Long-Life Components

- The frame is made from low-temperature-resistant alloy steel (e.g., Q345D or NM400) reinforced with stiffeners, offering both high yield strength (≥345 MPa) and toughness for stable operation in cold or high-altitude environments (–20 °C to –40 °C).

- Traction chains, carrying rollers, and return rollers are supplied by renowned international manufacturers (e.g., THIELE, Tsubaki, or leading domestic brands). With surface hardening and optimized lubrication, their design life exceeds 5 years under normal maintenance, significantly reducing downtime.

- The drive unit integrates overload protection (e.g., fluid coupling or torque-limiting inverter), automatically preventing damage from sudden overloads.

3. Sealed, Leak-Proof, and Smooth Conveying System

The apron plates adopt a special cross-sectional shape (e.g., Z-type or channel-type overlapping design). Adjacent plates overlap tightly (gap ≤ 2 mm), combined with side sealing plates to effectively prevent leakage of fine materials such as crushed ore or raw cement. This design keeps the working area clean and minimizes material loss.

Smooth transitions between plates also reduce material jamming, ensuring consistent conveying performance.

4. Precisely Adjustable Variable-Frequency or Hydraulic Drive System

- Two drive options are available—variable-frequency electric drive (standard) and hydraulic drive (for extremely humid or explosion-proof environments):

- Variable-frequency drive (VFD): Adjusts motor speed and gearbox ratio for stepless feeding rate control, typically between 30%–120% of rated capacity, enabling precise matching with downstream processing capacity.

- Hydraulic drive: Uses pressure sensors for real-time load feedback to automatically adjust pump displacement. This is ideal for operations requiring rapid start/stop or those with frequent load fluctuations.

conclusion

The apron feeder is particularly suitable for large, heavy, or highly abrasive bulk materials, such as uncrushed ore, construction waste, high-hardness minerals, or steel slag.

Heavy plate feeder plays a critical role in ensuring stable material supply and improving production efficiency in mining, mineral processing, cement, and metallurgical industries, as well as other continuous production lines.