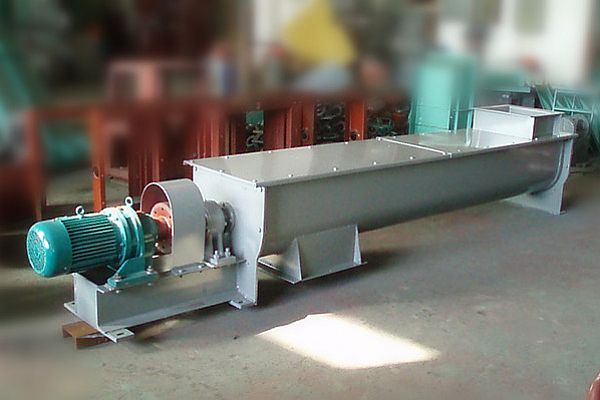

Spiral charging conveyor manufacturer,exporter

Working principle of screw conveyor

When the spiral shaft rotates, the friction material and the tank wall gravity generated by the material only in the blade push along the conveyor trough moving forward, the situation seems not rotate along the rotating nut screw for translational motion. The movement of the material in the intermediate bearing is dependent on the thrust of the material along the back. Therefore, the transport of materials in the conveyor, is a slip movement. In order to make the screw shaft in a more favorable state of tension, the drive device and the discharge port are generally placed at the same end of the conveyor, and the feed port as far as possible at the other end of the tail. The rotating spiral blade transfers the material to the material, so that the force of the material is not rotating with the screw conveyor blade is the material weight and the friction resistance of the screw conveyor casing to the material. Blade face delivery of materials according to a solid surface with different type, belt type, leaf surface type etc.. The terminal in the direction of material movement of the screw shaft of the screw conveyor have thrust bearings with material to spiral axial force, the captain a long time, should be added the middle suspension bearing.

Application

The spiral charging conveyor is widely used in various industries, such as building materials, chemical industry, electric power, metallurgy, coal carbon, food and other industries, is suitable for horizontal or inclined conveying powdery, granular and small bulk materials, such as coal, ash, slag, cement, grain and other materials, the temperature less than 200 DEG C. The screw machine is not suitable for conveying perishable, viscous and easy to agglomerate materials. In the concrete mixing station, the role of the screw conveyor has been reflected.