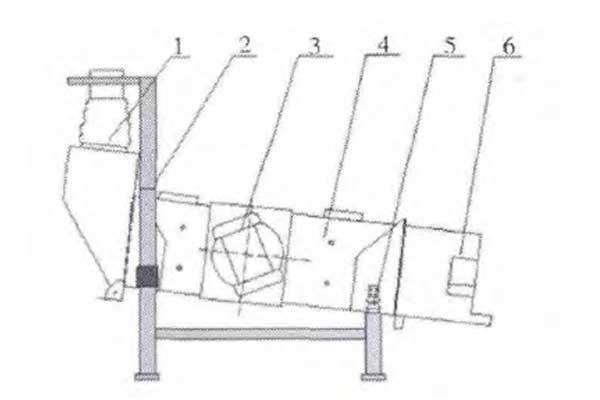

Structure of reciprocating linear vibrating screen

Reciprocating linear vibrating screen can remove large and small grains in grain. Reciprocating linear vibrating screen is widely used in grain cleaning and grading occasions by configuring the screening machine with wind selection or magnetic separation equipment to remove the light impurities, dust and magnetic impurities in the material. The movement of sieve surface of this type of vibrating screen is mainly driven by crank link mechanism, self transverse vibrator drive and vibrating motor drive. The vibration motor drive has the advantages of simple structure, good cleaning effect, the whole closed dust free and the vibration parameters such as the amplitude of the sieve surface adjustable, so it is easy to realize three, and it is more suitable for the pipeline operation and so on.

The device is composed of a feeding device, a frame, a vibrating motor, a sieve body, a vibration isolation spring and a discharging device. The reciprocating vibration sieves are excited by a double vibration motor, and the two machines with the same parameters are fitted symmetrically on the left and right sides of the screen. When the two vibration motor is synchronized and rotating, the exciting force perpendicular to the vibration direction is counteracted by the eccentric block, and the excitation forces along the vibration direction are superimposed on each other, thus driving the screen frame to the direction of the screen. A straight line movement. When the reciprocating linear vibrating screen works, the material is evenly distributed to the sieve surface through the feeding device. The large and medium impurities on the upper screen screen are discharged through the discharge mouth, and the undernees fall into the lower sieve surface to continue to screen. At this time the sieve surface on the lower screen is the required material, and the small impurities under the sieve are discharged from the small miscellaneous exit to realize the material cleaning.