Technical Advantages and Applications of Elastic rod vibration conveyor

A vibratory conveyor is a mechanized conveying device that uses an exciter to generate periodic excitation forces. These forces drive the material-carrying trough to vibrate in a specific pattern (typically directional linear or near-linear). Under the combined effect of inertia and friction forces, the material inside the trough achieves continuous sliding or throwing motion along a predetermined direction.

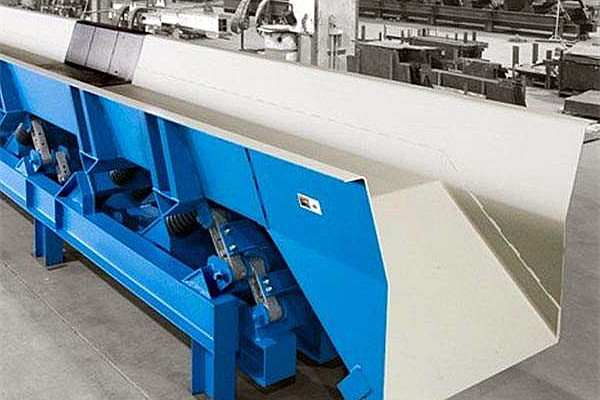

The Elastic rod vibration conveyor is a representative model of this category. It converts the uniform rotary motion of an electric motor into directional reciprocating linear vibrations of the trough through a crank-linkage mechanism. This design features stable operation, strong adaptability, and easy maintenance, making it suitable for continuous conveying processes that require high vibration stability.

Technical Advantages and Applications of Elastic rod vibration conveyor

The fully balanced design of the Elastic rod vibration conveyor marks its key technological breakthrough. By optimizing the mass ratio and motion phase relationship between the exciter and balancing body, the system delivers the following advantages:

Reliable Vibration Isolation and Reduced Foundation Load

With a dynamically balanced inertia design, most of the inertial forces (dynamic loads) generated during excitation are offset. As a result, the residual dynamic load transmitted to the equipment foundation or support structure is minimal—typically only 10%–20% of an unbalanced system.

Compact Structure with Strong Spatial Adaptability

The conveying trough is fixed on the support frame and does not undergo overall displacement during vibration—only the material moves within it. The excitation force is transmitted via the linkage mechanism to the trough. This “stationary trough + vibrating material” design simplifies the structure and eliminates the need for large swing spaces for moving parts, making it suitable for narrow workshops, interlayer installations, or restricted spaces.

Long-Distance and Large-Width Conveying Capacity

By extending the trough’s length and width and combining it with stable amplitude control (typically adjustable from 0.5 to 3 mm), the fully balanced Elastic rod vibration conveyor can meet the requirements of large-scale, continuous, high-capacity material transport.

Multi-Functional Integration for Enhanced Process Efficiency

1.Screening and Separation: Installing single or double-layer screens (customized by particle size) inside the trough enables simultaneous grading of coarse and fine particles (e.g., separating gangue from coal) or removal of foreign matter.2.Dual-Layer Synchronous Conveying: By modifying the balancing body into a secondary trough (symmetrically arranged below the main trough) and adjusting the excitation phase for opposite vibration, the system enables independent conveying of two material streams within the same space (e.g., raw materials on top, waste collection below) without additional equipment.

3.Combined Processing: Adjusting trough materials (e.g., heat-resistant stainless steel, wear-resistant coatings) and vibration parameters (frequency and amplitude) allows the conveyor to perform drying (via vibration-enhanced heat dissipation), cooling (air cooling + vibration heat transfer), sorting (aligned arrangement of particles), and dewatering (removal of free water from wet materials). This transforms the conveyor into an integrated “conveying + processing” system.

Wide Material Adaptability

The equipment can reliably convey high-temperature materials (up to 400 °C, such as molten slag), corrosive materials (chemical raw materials), high-hardness particles (mineral sands), and fragile materials (glass beads). By adjusting trough materials (e.g., 316L stainless steel for corrosion resistance, polyurethane lining for abrasion resistance) or applying surface treatments (e.g., plating, coating), it can meet the special requirements of various industries.

Low Maintenance Cost and High Operational Reliability

The moving parts of a Elastic rod vibration conveyor (such as linkages and bearings) require only a few key lubrication points (mainly at rotating shaft bearings). With no complex rotary friction pairs (such as gears or chains), it has lower lubrication demand and reduces failure rates by 30%–50% compared with conventional conveyors (belt or screw conveyors). Modular wear parts (springs, linkage sleeves) allow for localized replacement during maintenance, minimizing downtime and operating costs.

Conclusion

With its vibration isolation from fully balanced design, compact installation flexibility, low-noise environmental performance, and integrated multi-functionality, the Elastic rod vibration conveyor has become an essential piece of equipment for continuous bulk material handling in industries such as mining, metallurgy, building materials, and chemicals.