Matters needing attention during trial operation of vibrating screen

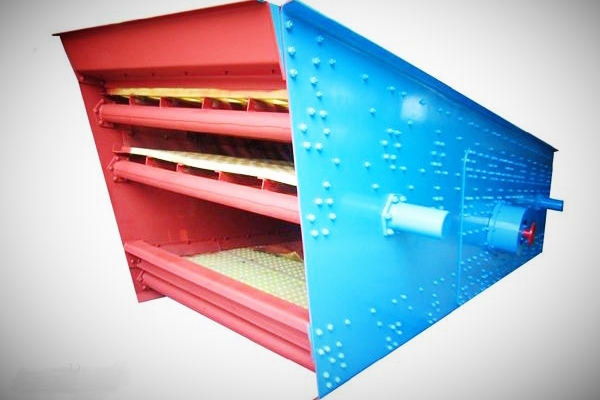

The vibrating screen machine works with the vibration of the reciprocating rotating type produced by the vibration of the vibrator. The upper rotating weight of the vibrator makes the surface of the screen generate the plane cyclotron vibration, while the downward rotating hammer makes the screen surface produce the conical rotary vibration, and the effect of the combined effect makes the screen surface have the complex rotation vibration. Its vibrational trajectory is a complex space curve. The curve is projected into a circle on the horizontal plane, and the projection on the vertical plane is an ellipse. The amplitude can be changed by adjusting the exciting force of the upper and lower rotating heavy hammer. While adjusting the space phase angle of the upper and lower heavy hammer, the curve shape of the motion track of the screen can be changed and the motion track of the material on the screen can be changed.

The technology of screen blocking in vibrating screen is advanced, and it does not need to jump ball clear net. It is better to prevent the blockage of screen and no pollution, so as to ensure the continuity of screening. The equipment has the characteristics of low noise, all closed, dust not flying, more environmental protection and so on. The screening efficiency of the vibrating screen is high, the quality is light, the series is complete and varied, the level is many, and the screening of dry material can meet the demand.

The following points should be paid attention to in the trial operation of the vibrating screen separator.

1.Close the power switch, run 20 - 30 minutes by air, the motor should run counter clockwise in general, if the direction is wrong, please adjust the three phase power.

2.We should confirm that the vibration motor is running in rated current. When starting, especially at low temperature, the current will be slightly higher, but in 20 to 30 minutes, it should be reduced to the rated current value.

3.No abnormal voice can happen in the sieving machine. If abnormal voice happens, it should be shut down for checking quickly. The occurrence of abnormal voice is usually caused by loosening of the fastening part. Special attention should be paid to the fastening of all parts, especially when reassembled and reassembled after transportation and decomposition. There is an instantaneous resonance area (1-3 seconds) when the screen starts and stops. At this time, the amplitude and noise will increase obviously, which is a normal phenomenon.

4.after the transfer of air, a small amount of material can enter the screening machine through the feed port, and then slowly increase to the amount of material needed and able to bear. At this time, the adjustment of the heavy hammer should be carried out according to the discharge condition of the net surface, so that the efficiency of the screen can reach the best state.